Analysis of the advantages of different materials of valve covers

Click:2067Edit: Admin

Click:2067Edit: Admin Time:2025-10-13 10:13:54

Time:2025-10-13 10:13:54

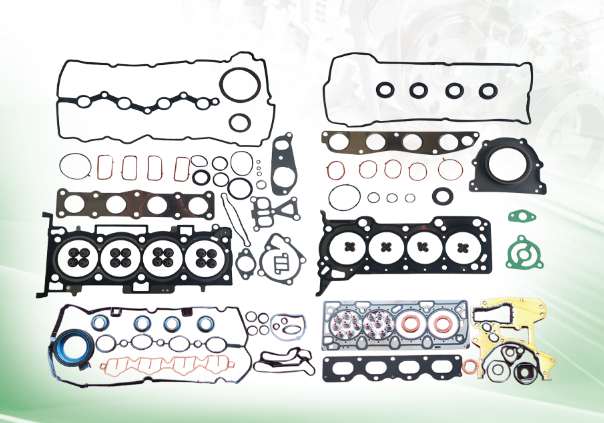

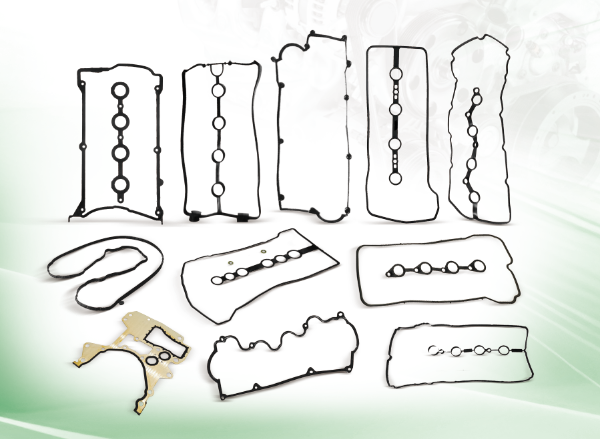

Valve chamber gasket cover is a key engine seal, and its material directly affects the sealing performance, durability and cost. Currently, there are several mainstream materials on the market, each with its own significant advantages:

1. Nitrile rubber (NBR) - economic and durable choice

- Advantage: Good oil resistance, abrasion resistance and anti-aging performance, cost-effective. It is the standard choice for most OE packages and the independent aftermarket, and can excel in dealing with mineral oils and the common environments found in engine compartments.

- Scenario: Suitable for standard engine conditions in most family cars and commercial vehicles, it is a reliable choice for comprehensive and balanced performance.

2. Fluoroelastomer (FKM/Viton) - High Performance Representative

- Advantage: excellent high temperature resistance (can withstand temperatures above 200°C for a long time), excellent resistance to fuel, synthetic oil and chemical corrosion resistance. Its sealing life far exceeds that of ordinary rubber, and its performance is stable under severe working conditions.

- Scenario: Designed for high-performance turbocharged engines, high-power tuned cars or models using full synthetic oil, it is the top solution to the problem of high-temperature oil seepage.

3. Silicone Rubber (VMQ) - Wide Temperature Range Specialist

- Advantage: The biggest feature is that it has an extremely wide operating temperature range (-60°C to +200°C or more), excellent resistance to high and low temperatures, and good elasticity retention. However, it is slightly less resistant to oil penetration than fluoroelastomer.

- Scenario: Widely used in modern engines that have to cope with extreme high and low temperature cycles, but make sure that the formulation is optimized for oil resistance.

4. Metal gaskets (usually multi-layer steel) - sealing and structural integrity

- Advantage: Usually used in combination with plastic or aluminum valve covers. Provides extremely high sealing pressure and structural strength, is virtually unaffected by oil and temperature changes and has an extremely long life.

- Scenario: Common in many new modern engine designs, achieving a combination of light weight and high sealing performance, but replacement usually requires an assembly change.

Selection Advice: Liang Chang Auto Parts can provide a wide range of valve cover materials according to the technical requirements of different engine models, ensuring that every customer is matched with the most suitable and reliable sealing solution that effectively eradicates oil seepage and protects the core of the engine.

- Previous Article:Industry Focus: Engine Overhaul Kit Demand Soars, Technology Upgrade and Supply Chain Efficiency Become Key to Competition

- Next Article:

-

Xingtai Liangchang Auto Parts Co., Ltd. successfully participated in the Shanghai Frankfurt Auto Parts Exhibition and achieved great success.

-

Xingtai Liangchang Auto Parts Makes Its Debut at Egypt International Auto Parts Exhibition, Taking a Solid Step in Deepening Its Presence in the Middle East and African Markets

-

Industry Focus: Engine Overhaul Kit Demand Soars, Technology Upgrade and Supply Chain Efficiency Become Key to Competition

-

Analysis of the advantages of different materials of valve covers

Online consulting

If you have any questions, please contact our online customer service staff immediately

Ziliang@liangc.cn

Ziliang@liangc.cn +86-13931944997

+86-13931944997

English

English

Español

Español اللغة العربية

اللغة العربية

Home

Home Whatsapp

Whatsapp Email

Email